Diesel Exhaust Fluid (DEF) is a solution used in modern diesel engines equipped with Selective Catalytic Reduction (SCR) systems to reduce the emission of nitrogen oxides (NOx) from the exhaust gases. It is also known by its brand name AdBlue® in some regions. DEF is a crucial component in the effort to meet strict emissions standards, particularly in commercial vehicles and heavy machinery,

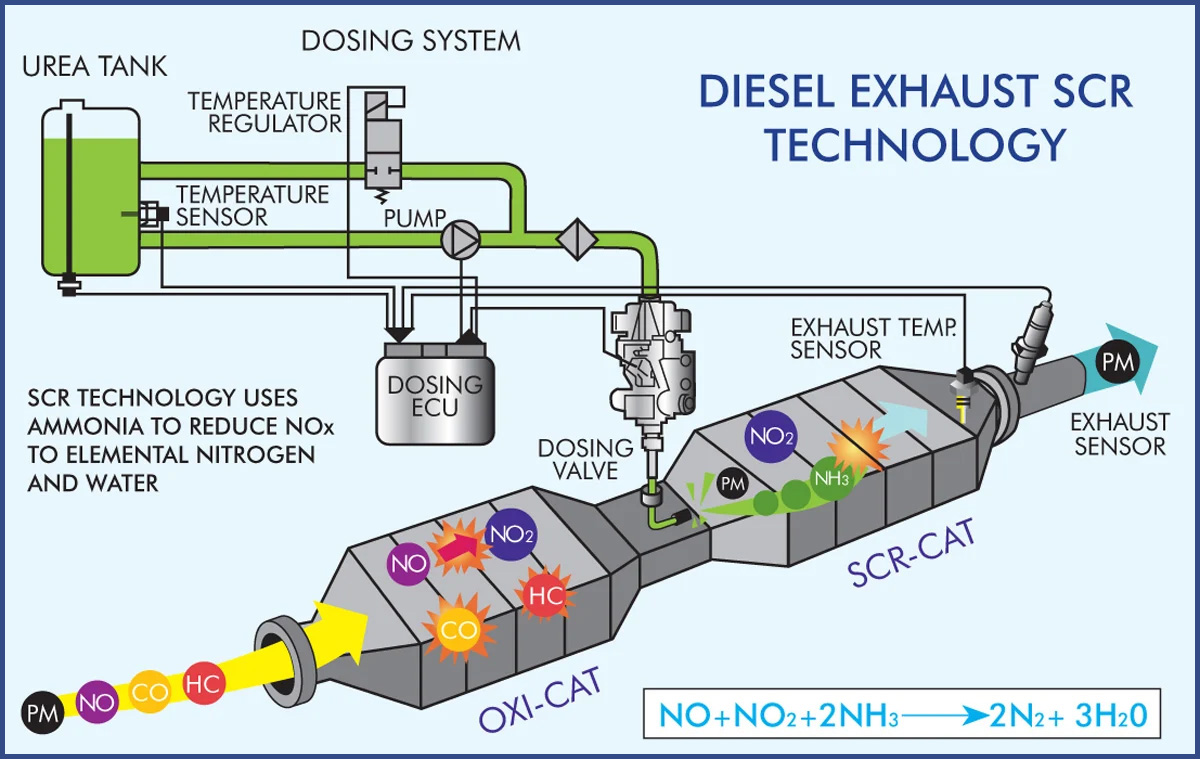

DEF is composed of high-purity urea and deionized water. When introduced into the exhaust stream, DEF breaks down into ammonia and carbon dioxide under high temperatures. The ammonia then reacts with the NOx gases in the presence of a catalyst within the SCR system, converting the harmful nitrogen oxides into harmless nitrogen and water vapor. This process helps to significantly reduce the emission of pollutants responsible for smog, acid rain, and other environmental issues

DEF is typically stored in a separate tank within the vehicle and is metered into the exhaust system as needed. The usage rate of DEF is typically around 2-3% of diesel fuel consumption, but it can vary depending on factors such as engine load, operating conditions, and vehicle design.

Using DEF is essential to comply with emissions regulations, and many diesel-powered vehicles and equipment, including trucks, buses, and construction machinery, have adopted SCR technology alongside DEF injection systems to meet these standards. Regular monitoring and refilling of the DEF tank are crucial to ensure the proper functioning of the SCR system and to prevent engine performance issues.

Generic Name:

Diesel exhaust fluid

Diesel exhaust fluid Blue DEF eliminates nitrogen oxide emissions.

Product Description:

DEF is a Liquid Urea solution used as a Diesel exhaust fluid for reduction of NOx concentration in the diesel exhaust emission from diesel engines combustion. Diesel Exhaust Fluid Blue DEF is a crystal clear 30% - 32% aqueous solution of urea.

Product Application:

Diesel Exhaust Fluid Blue DEF having various application: The most important use of DEF is for reduction of Nitrous Oxide (NO). DEF helps complete combustion of soot and to prevent them exhausting unburnt fuel.

It is used in NOx reduction and as a nutrient component in organic waste water treatment plants.

In the manufacture of liquid feed supplement for ruminant animals.

In plywood and core board adhesives.

Textile processing and coatings.

In some paper coatings.

Urea is also consumed in animal feeds, other chemical manufacturing, as an alternative to rock salt for de-icing, as an effluent treatment plant or fermentation nutrient and is growing in diesel emissions control.

Product Procedure:

Diesel Exhaust Fluid (DEF) can be dosed directly into the exhaust pipeline, where the urea molecule rapidly vaporizes and dissociate into ammonia and carbon dioxide. This process prohibits the formation of Nitrous Oxide (NOx) and finally Ammonia (NH3) chemically changes into water (H2O) and nitrogen (N2), which is not harmful; and these are then released through the exhaust.

Product Note:

Handling:

Avoid contact with skin, eyes, and clothing.

Storage: Keep storage tanks and containers closed and contents protected from the dust, dirt, and moisture. Clean storage tanks on a regular schedule based on inspection and experience. Have storage tanks, containers, and transfer systems properly labelled for contents. Have procedures for determining product quantity in storage tanks and for accepting deliveries. Use tanks, transfer lines, pumps valves and process instrumentation designed for this material using approved materials of construction. Some materials commonly used are stainless steel, some plastics, and FRP, mild steel, iron and nonferrous metals will be damaged by corrosion. Consult engineers if needed.

| Chemical Formula | CO(NH2)2 |

| CAS Number | 57-13-6 |

| Molecular Weight | 60.056 |

| Specific Gravity | 1.140 |

| pH | 6.5 – 8.5 |

| Salt-Out Temp | 62˚F (18˚C) |

| Colour | Clear Liquid |

| Odor | Slight Ammonia Smell |

| Urea 23% Nitrogen | 50% |

| Turbidity | 5 ppm |

| pH | 8.5 Max |

| Ammonia | 0.03% |

| Biuret | 0.25% |

| Ash | 35 ppm |

| Iron | 2 ppm |

| Chloride | 10 ppm |

| Colour-Max | 0 (APHA) |

| Alkalinity – wt. (NH3) Max |

0.05% |

Emissions Regulations:

Governments around the world have been implementing more stringent emissions regulations to reduce the environmental impact of diesel engines. This has led to a higher adoption of DEF and Selective Catalytic Reduction (SCR) systems in vehicles and industrial equipment.

Commercial Vehicles:

The market for DEF is particularly significant in the commercial vehicle sector, including trucks, buses, and other heavy-duty vehicles. These vehicles are often subject to strict emissions standards, and DEF/SCR technology is a common way to comply with these standards.

Agricultural and Construction Machinery:

DEF usage has also been growing in agricultural and construction machinery, as these machines often use diesel engines and need to meet emissions requirements

Automotive Industry:

Some passenger car diesel engines also use DEF/SCR technology, especially in regions with stringent emissions regulations

Fluid Availability:

DEF is widely available through various channels, including fuel stations, automotive parts stores, dealerships, and online retailers. The accessibility of DEF has contributed to its broader adoption

Global Market:

The market for DEF is not limited to any specific region; it has a global presence due to the worldwide focus on reducing emissions. North America, Europe, and Asia are among the prominent regions for DEF consumption

Price and Supply:

The price of DEF can vary depending on the region and market conditions. Since DEF is composed of urea and water, factors that influence urea production and availability can impact DEF prices

Industry Players:

Various companies are involved in the production, distribution, and marketing of DEF. Some of these companies are specialized in DEF production, while others are major players in the automotive or chemical industries

Environmental Impact:

The increased adoption of DEF technology has helped in reducing harmful emissions from diesel engines, contributing to improved air quality and reduced environmental impact